Most orders for IN STOCK items placed by 12PM CST M-F ship SAME DAY. Orders for custom items and prints may take additional time to process.

Do yourself a favor and use this wizard! Especially if this is your first time. It removes all the guess work.

I like to screw 3″ drywall screws into the four corners of the shutter. This allows me to rest the screws on some blocks or saw horses. Once you’ve finished painting one side, you can easily flip it over using the screws and paint the other side. I recommend letting the shutter dry overnight before hanging it.

Hey Guys! It’s Mike, from The Geek Pub! In this episode we’re going to make Plantation Shutters. And we’re going to do it for about one third of what they cost at the local home improvement store.

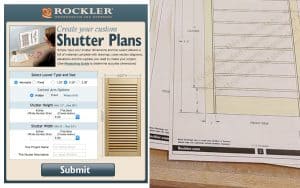

The first step to making plantation shutters is to take measurements from the window, and then subtract 1/4 inch from each dimension. Follow that by heading over to Rockler.com and click on the plantation shutter tool! This tool will create a detailed PDF plan file and cut list. It also provides a detailed order list that you can use to order everything from Rockler if you’d like to do so.

Well, I went ahead and ordered from Rockler and few days later a brown box arrived on my front door with all of my goodies inside, saving me a drive to the lumber yard! I received two 1×6 basswood sections for the rails. Two 1×2 basswood sections for the stiles. A pack of stainless steel nails. Louver pins and hinges. A hidden control arm. Several pre-router sections of louvers. And finally the Rockler Shutter System Jigs. . But we’ll talk more about in a minute.

We’ll want to run all of the sections of wood through the planer and take off about 1/32 of an inch on both sides. Rockler says this isn’t necessary, but the wood I received did not have a smooth surface. But that’s OK, because it only takes just a second. You could sand it smooth if you don’t have a planer. Follow that by marking the boards based on the plan dimensions and cutting them to their final dimensions using a miter saw or crosscut sled.

I used my table saw to rip the stiles down to the proper dimensions, but they could also just go a few passes through the planer. Then rip the rails down to the final plan dimensions as well. The next step requires cutting some rabbets. I did this using a dado stack and a sacrificial fence on the table saw. You could use a router for this job. These rabbets will allow the top and bottom louvers on the shutter to tuck into the shutter fame when the shutter is in the closed position.

Once those steps are complete, lay everything out on a table and align all of the boards. I like to label each board at this point to make sure they don’t get mixed up.

My joinery of choice for shutters is dowels. So I lined up and marked all of the edges to be drilled. These lines mark where to drill the holes using my doweling jig. The doweling jig makes it super easy to drill the holes. Just line up these little markers with your pencil line and tighten to clamp it in place. It works on the sides of the boards, or the ends exactly the same.

Now is a great time to test fit everything before we go to the next steps. I like to dry fit the pieces to gather and place the shutter in the window, checking to make sure all the right clearances are in place. Correcting mistakes after this point will be much harder.

Now go ahead and do a quick sanding to smooth everything out and remove any marks from the previous steps. You’ll want to use a shutter cutter router bit to add the decorative edges on the stiles. You can pick this bit up from Rockler or any home improvement center. Follow that up by adding a 45 degree chamfer on all of the rails. This is really optional, but I like to add a round-over on the rabbets we cut earlier. This provides a nice clean look when the shutters are closed.

Now it’s time to drill all of the louver pin holes in the stiles. And that’s where the shutter jig makes all of the difference. Place the stiles face to face and then clamp the shutter jig in the middle of them. Then all that’s required is to drill the holes using the self centering drill bit provided in the kit.

When you run out of holes in the jig, you just slide it down and use these 1/4” pins to quickly re-align it. That’s it and your back to drilling! Using my crosscut sled and a stop block set to the right length I cut all of the louvers down to size. Using this method makes it easy to make repeated cuts of the exact same length. Once that’s done we need to move the stop block by 1/8” and then cut notches in the louvers to accept the hidden control arms.

The Shutter System comes with a jig for drilling the ends of the louvers. You’ll need a center hole on each side, and one side needs a control arm hole Each louver receives a shutter pin on each end. One lover receives a special tensioning pin that comes in the pin packs.

Now its time to start the glue up. This is a process that you can’t really stop once you start. So make sure you’ve got everything ready. It’s a somewhat complicated and rushed process. The more louvers the more time you need. I find it easier to only insert everything one end at time and slowly compress the joints as I go. This sped up about 8X to give you an idea.

At this point its critical to make sure everything is square and lined up. I will be impossible to fix after the glue dries. I like to tighten the clamps, loosen them, and the re tighten them again. Once you’re done it should look like this. You’ll want to let them sit over night in the clamps before moving on.

The next step is paint. I used my HVLP sprayer and our trim color to paint the shutter. But you can certainly paint them with a brush if you don’t have a sprayer. Once the paint dries its time to install the hinges. I installed them 3 inches from each end. Basswood is a stringy wood so be sure to drill slow and not to over tighten your screws.

Take the hidden control arm and cut it to the proper length. In my case 12 louvers. Then use the stainless steel nails provided to attach it to each lover. The hidden control arm makes for a really clean look and allows the movement of one louver to move all of the louvers.

All that’s left to do is screw the shutter into the window frame. I used magnetic clips to keep my shutters closed. I feel like this provides a very clean look and simple operation, but you can also use pins or latches if you prefer. The magnet just attaches to the top and bottom of the window frame.

And that’s it! You’ve just built and installed your very own Plantation Shutters and minus my time, it cost me approximately one third what our local home improvement store quoted. Saving money and gaining bragging rights! Now that’s what I call a win-win.

If you like our content maybe consider upgrading to Premium. You’ll get access to

15 Responses

I don’t have any plantation shutters but I do have some cupboard doors in the workshop that have the same design. Some of the slats have broken, do you have any tips for fixing them?

Nice vid but WAY beyond my ability. I do, however, love the color you used… the same green as your cabs & window trim. What mfr/color is it?

It’s called Adaptive Shade.

Hi Mike. Great video. I just bought my handheld router and table to complete the tools in need to build my shutters. I’m about to pull the trigger and order the wood and jigs all from Rockler. Your video helped me decide to attempt them. -Thanks. One question. Did painting your shutters after having assembled them cause them to stick in place due to dried paint? Thanks again.

No. The dowel pins are made of plastic and the paint does not stick to them.

Mike the design wizard only allows for a maximum width of 24 inches…. did you just add the extra width to allow for your 35 inch wide shutters onto the rails and louvers? Thanks

There is a link to email Rockler for bigger plans.

Thank you

Pretty good method but not at all inovative. D I Y usually translates (or should, to be useful) to a project that homeowners with medium level skills can accomplish. I call your article a fail in that regard. The down pins for fame is fine, but you gotta do better with the louvers and pins! Hows about assemble the frame and the router out pockets for the pinned louvers!? And we always paint before the pin and socket assembles! Maybe lets call your arlicle DIY+!

I never once claimed that I was going to demonstrate such a thing. My only claim was that I was going to show “How to Make Plantation Shutters”. If you added DIY, on the cheap, or any other such words, that’s all on you my friend.

Thanks for the video, Mike.

do you have the option for 2″ louvers with a hidden tilt?

Yep.

4.5

Great video. I know it takes a lot of effort to put this together. Thank for sharing your knowledge.